Innovative mesh solutions for the automotive future

23. September 2022

Building of the Year Award

1. December 2022Maximum energy efficieny for corrugated board production

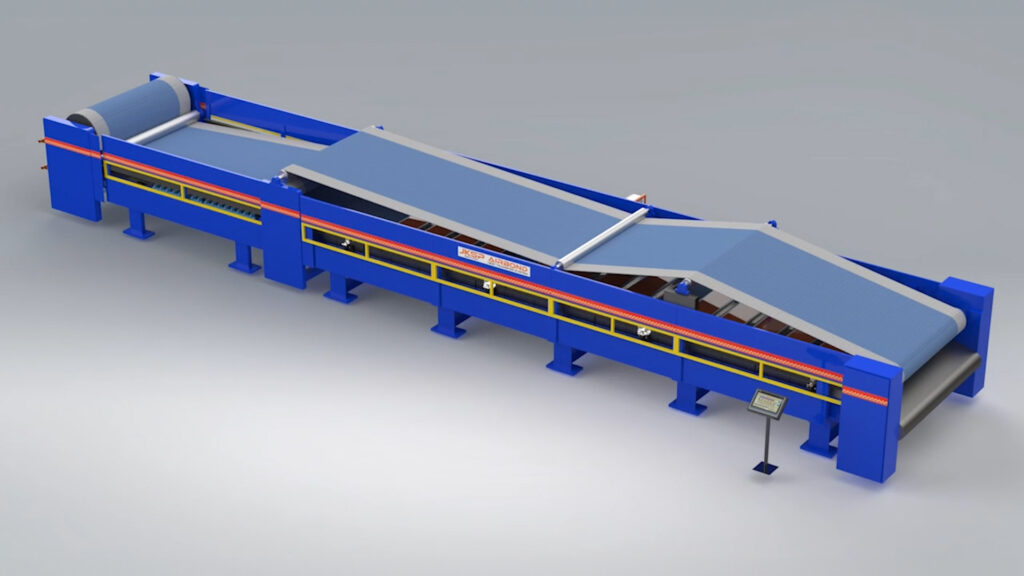

Lower heating and energy, reduced maintenance costs, and improved performance. With the market launch of the BLUEBACKER corrugator belt, GKD offers corrugated board manufacturers clear advantages for their production process with just one product. This innovative belt for the double facer is equipped with proven CONDUCTO® technology. This ensures constant electrostatic dissipation and prevents the corrugated board from adhering to the belt.

GKD process belts prove their potential as a solution millions of times per day in industries throughout the world. The same is true of the new BLUEBACKER. This all-around solution for corrugated board production consists of a robust and open mesh design and combines two functions in one product, with the doublebacker belt succeeding as both a top and lower belt. During operation, corrugated board manufacturers benefit from particularly high efficiency and sustainability. Energy savings of up to 40 percent can be realized, depending on the specific conditions in which the belt is used. Production speed can be increased by 50 percent and drive energy reduced by 15 percent. Together, these values ensure maximum energy efficiency in corrugated board production.

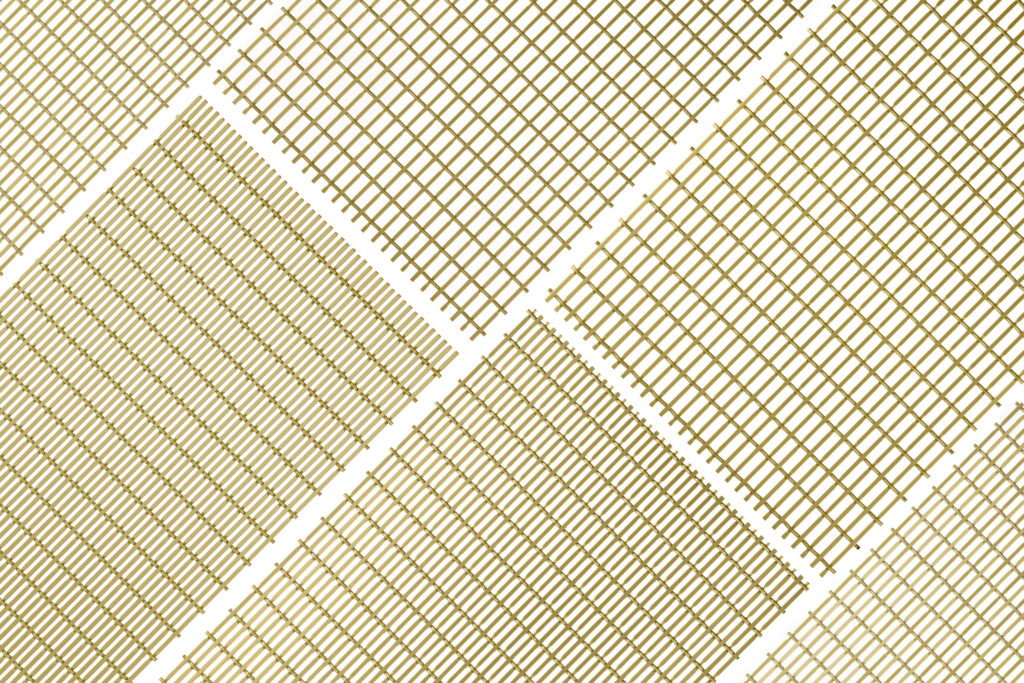

In detail, the BLUEBACKER mesh consists of a unique multilayer combination. The base mesh made of monofilaments absorbs forces and loads during the production process. It prevents the risk of elongation of the belt throughout its entire service life. This guarantees a high degree of cross stability and requires less assembly work. Combined with the thermosetting of the belt, the special mesh design results in consistent dimensional stability.

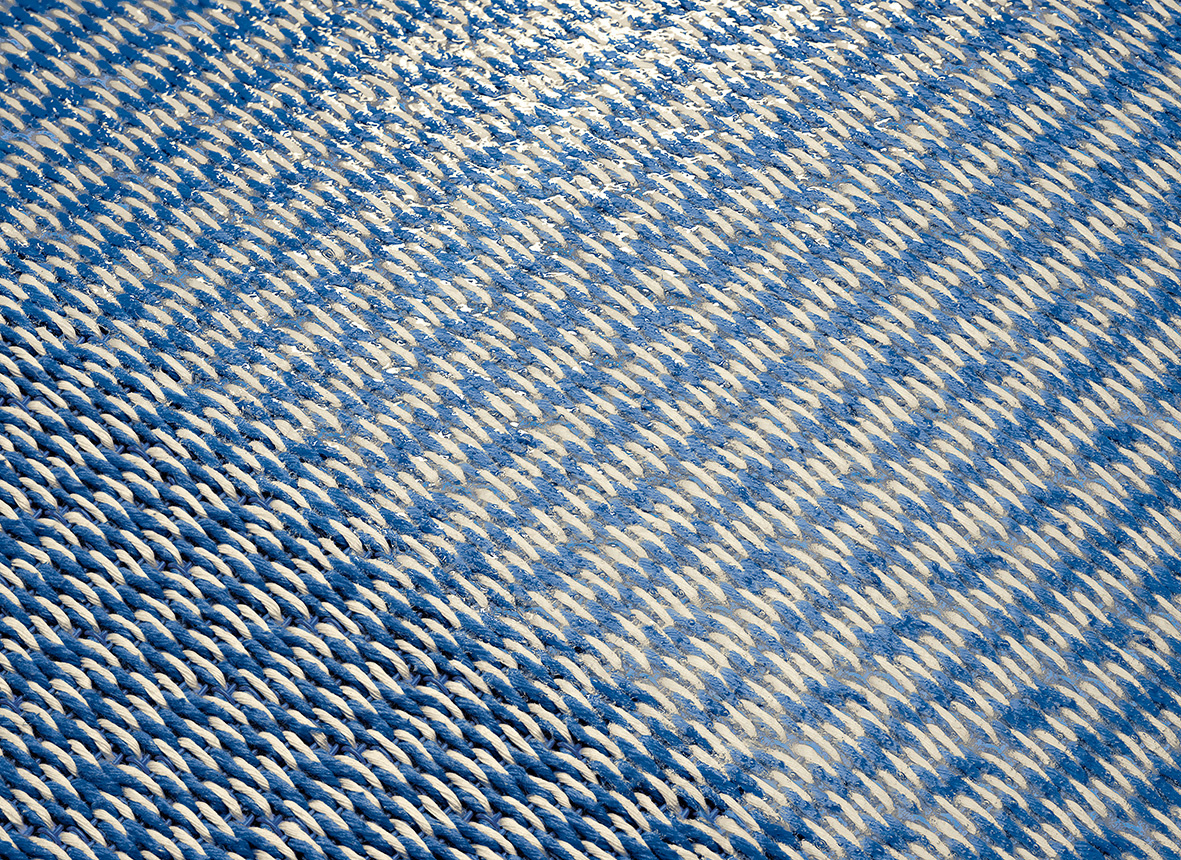

The transport/traction level is produced from a special staple fiber yarn and aramid. This ensures the corrugated board is safely transported and securely gripped. Wear is minimized, which leads to a longer service life with no adhesion problems. The edge reinforcement of this mesh level protects the belt from lateral abrasion, even when working with narrow production widths. The special staple fiber yarn generates an ideal balance of moisture absorption and release. Noise emissions are also reduced.

The third element, an inner bronze wire, generates a constant electrostatic discharge so that the corrugated board is not able to adhere to the belt. This CONDUCTO® technology also significantly reduces the risk of fire.

In its uncoated form, the lower belt is suitable for all corrugated board production systems, press systems, and operating speeds. In the silicone-coated version, paper grip is significantly increased, which makes the belt especially well suited for use with heavy corrugated boards and papers with a smooth surface. The special coating is abrasion-resistant and high-temperature resistant, guaranteeing a long, trouble-free service life and consistent quality/product properties, even when used at maximum production speed.

With the market launch of the BLUEBACKER, mesh specialist GKD offers its industrial customers another solution for optimizing production processes. At the same time, the company reaffirms its pledge to make our world healthier, cleaner, and safer.

Contact