Multi-faceted weaving expertise

10. June 2022

Stay cool with external metal fabric as effective solar protection

30. August 2022Efficient mesh solutions for sustainable production processes

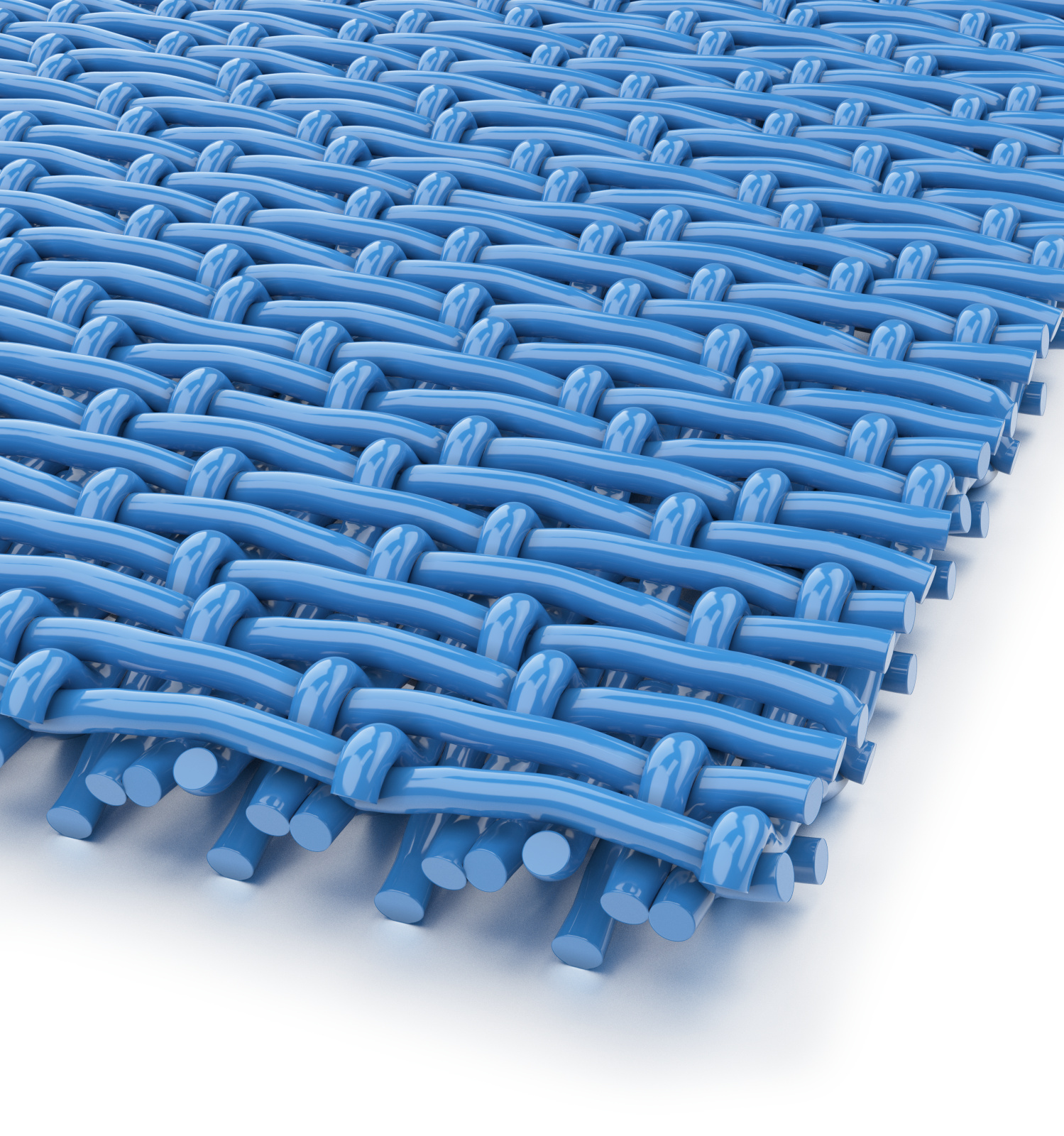

The GKD stand showcases the solution potential of GKD high-performance meshes with a wide range of metal and plastic structures in reliably reproducible quality. The key focuses of the sector specialist with almost 100 years of experience are renewable energies and energy efficiency, CO2 capture, as well as filtration, separation, and drying for water processing in the chemicals, mining, and other industries.

Green hydrogen is considered a ray of hope in the field of climate protection. As global market leader for solutions produced from metal, hybrid, and synthetic fabrics, GKD supports its efficient use in industrial applications. After all, the high-grade technical weaves are used for the production of hydrogeny through electrolysis and also for its conversion into energy. Suitable fields of application include refineries, iron and steel production, and the chemicals industry. Green hydrogen is also used as fuel and energy storage in the smart grid.

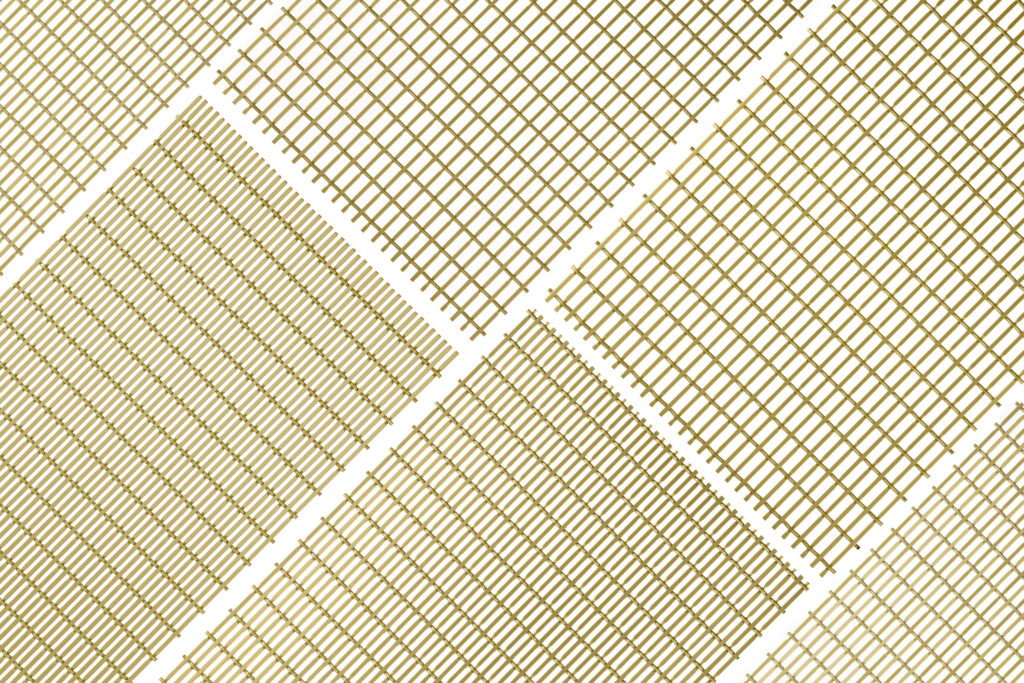

GKD provides technical weave for the electrode material, spacers, and power distributors used in the electrolysis process. The electrochemical, structural, and mechanical properties of the materials are optimized on a customer-specific basis for both alkaline water electrolysis and solid oxide electrolyzer cells (SOEC). They increase the efficiency of the reaction processes and power generation. The special fine fabrics produced from wires are available for various types of fuel cells and different manufacturers. The porosity, conductivity, and shape of the materials allow them to be used for a broad range of applications within various types of fuel cells.

GKD produces Stirling engine regenerators in individual designs for use in different types of power units from various manufacturers. GKD technology encompasses the entire vertical range of manufacturing – from fabric/mesh production, through application-oriented post-treatment, right up to production of sintered regenerators and those with housing and mesh layers as ready-to-use assembly parts.

In the direct air capture (DAC) process, GKD filter cartridges secure reliable filtration of carbon dioxide from the air. Not only do they hold the adsorbents reliably in place, they can also withstand the temperatures encountered during heat treatment to release the carbon dioxide from the adsorbents.

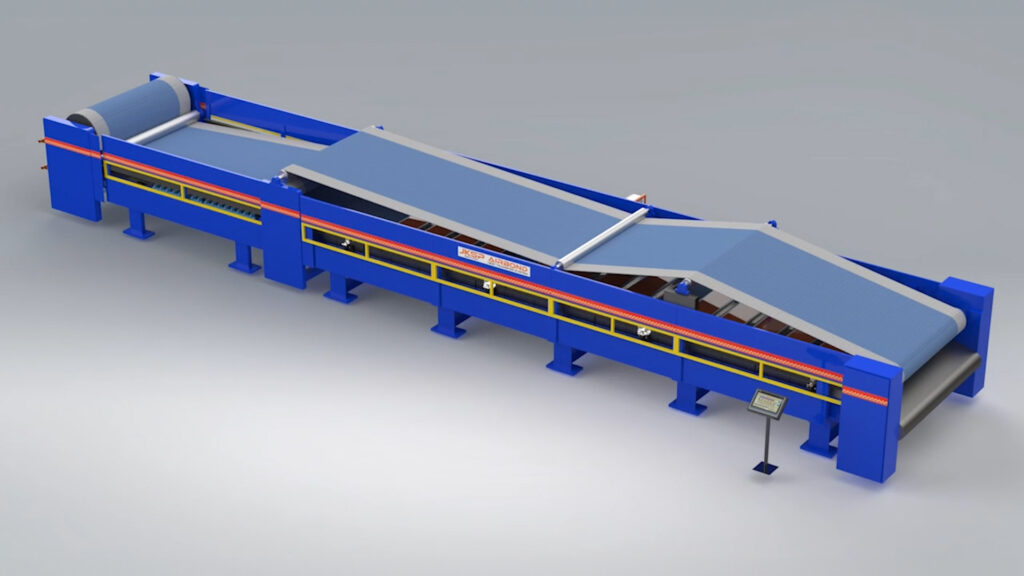

The focus at Achema for the chemicals segment is on drying, conditioning, maturing, and phosphorus recovery, while the focus for mining is on the treatment processes in mineral mining, such as classification or process water filtration.

Whether environmental technology, chemicals, or water processing: GKD provides important elements for a very wide range of sectors that help them meet their sustainability goals and secure greater process reliability, productivity, and efficiency. As the world’s leading technical weavers, offering integrative consulting, development and manufacturing expertise, GKD is the solution partner for fabric designs developed on an application-specific basis. The process-optimized material combinations and wide range of weave types, coupled with innovative weaving technology, open up huge solution potential.

Contact