Woven fabric and mesh solutions for the challenges of tomorrow

We aim to make our customers more successful and sustainable. Our courage and determination to improve things are what drive us.

“Our capacity to innovate is what drives our constant development and evolution. It describes our ability to get things moving and our speed, as well as our courage to break new ground, transform challenges into opportunities, and constantly reinvent ourselves. In other words, it is the key to our solution expertise.”

Lara Kufferath

Chief Digital & Transformation Officer

Perfectly tailored fabric solutions for markets and customers

Our capacity for innovation has helped us secure leadership in our markets. We continuously refine and optimize our products. We find completely new solutions and achieve sustainable progress for sectors driven by global macro trends. Examples include the medical and pharmaceutical industries, the food industry, as well as sustainable packaging or optimization of processes used in raw materials extraction.

For us, the following applies to every product: ENGINEERED IN GERMANY.

Our engineers engage in constant dialog with customers and employees from production. This ensures that they are always in touch with the requirements of the market and experience first-hand how our products and solutions can be made even better. We collaborate intensively with international research institutes to develop the leading-edge products of the future.

Innovations as a driving force

Wire meshes that make electric mobility safer, that accelerate production and use of green hydrogen, or help filter even the smallest plastic and pollutant particles from water – it is with these and many other solutions that the GKD Group opens up new perspectives and competitive advantages for its customers.

GKD locations

and partners in our

market segments

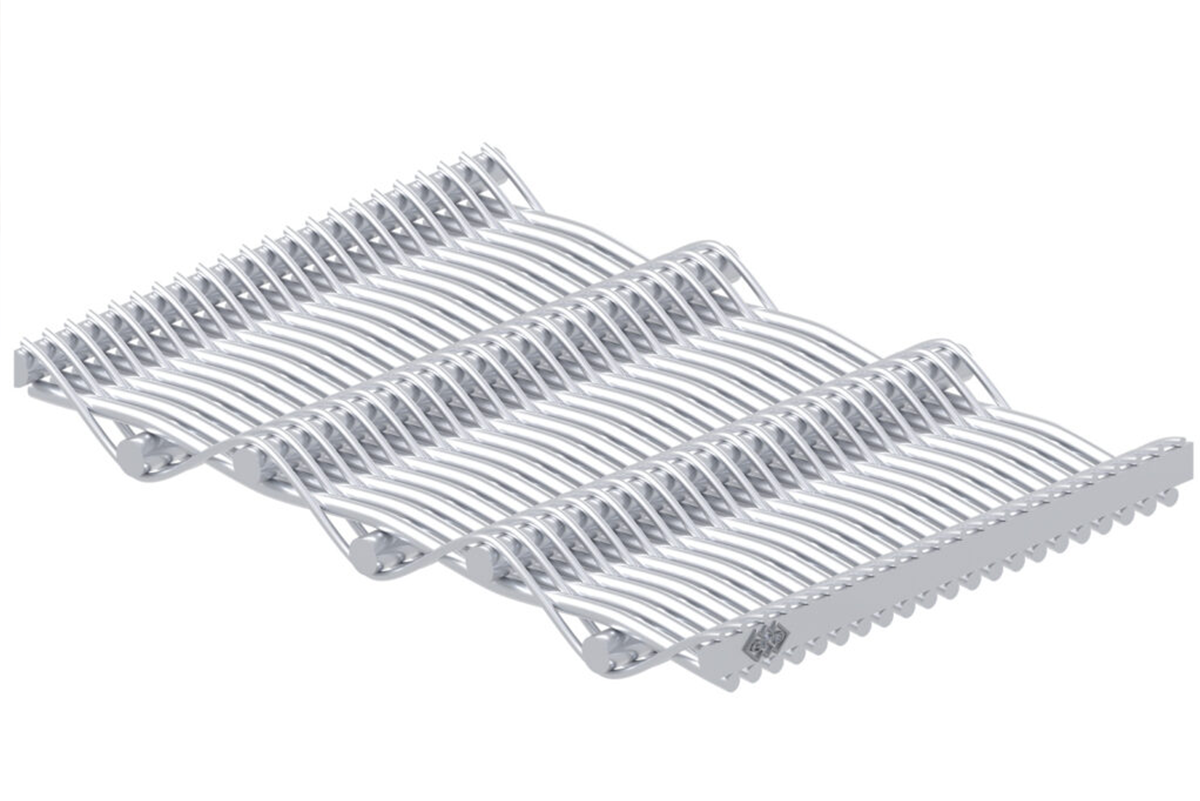

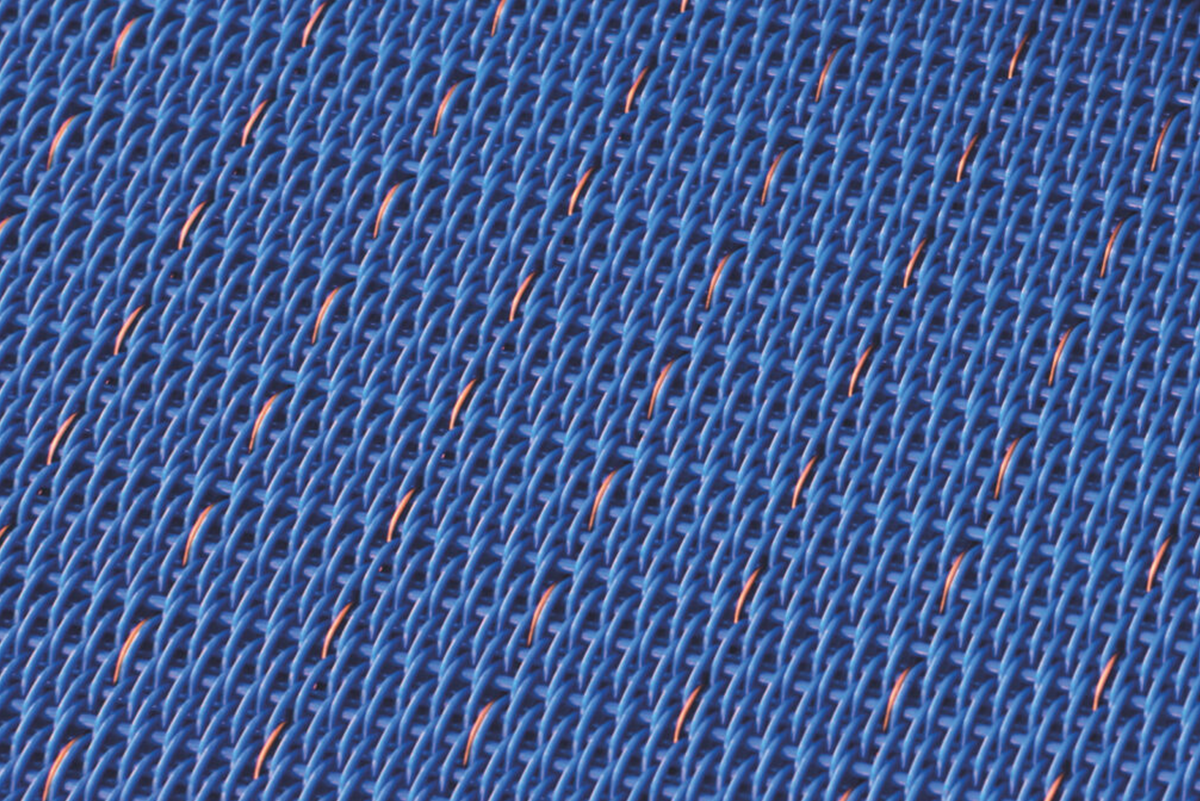

2022 – BLUEBACKER: Maximum energy efficiency for corrugated board production

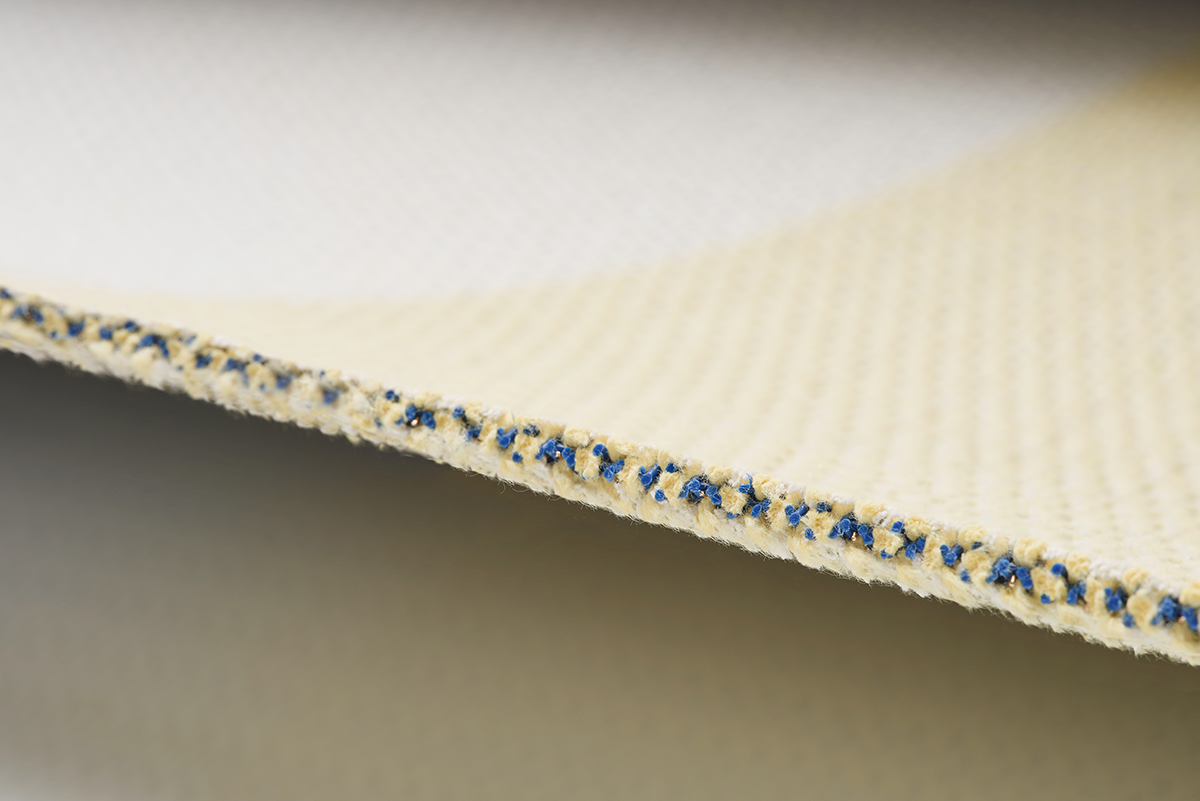

GKD introduces the BLUEBACKER corrugator belt, offering clear advantages for corrugated board manufacturers: lower heating and energy costs, reduced maintenance expenses, and improved performance. The belt utilizes proven CONDUCTO® technology for constant electrostatic dissipation, preventing corrugated board adhesion. The innovative BLUEBACKER mesh features a unique multilayer combination. The monofilament base mesh ensures high cross stability, no elongation, and easy assembly. The transport/traction level, made from special staple fiber yarn and aramid, securely grips and transports the corrugated board with minimal wear. The inner bronze wire provides constant electrostatic discharge, reducing adhesion and fire risks. The uncoated lower belt suits all corrugated board production systems, press systems, and operating speeds. The silicone-coated version offers increased paper grip for heavy corrugated boards and smooth-surfaced papers, with high-temperature and abrasion resistance for consistent quality at maximum production speed.

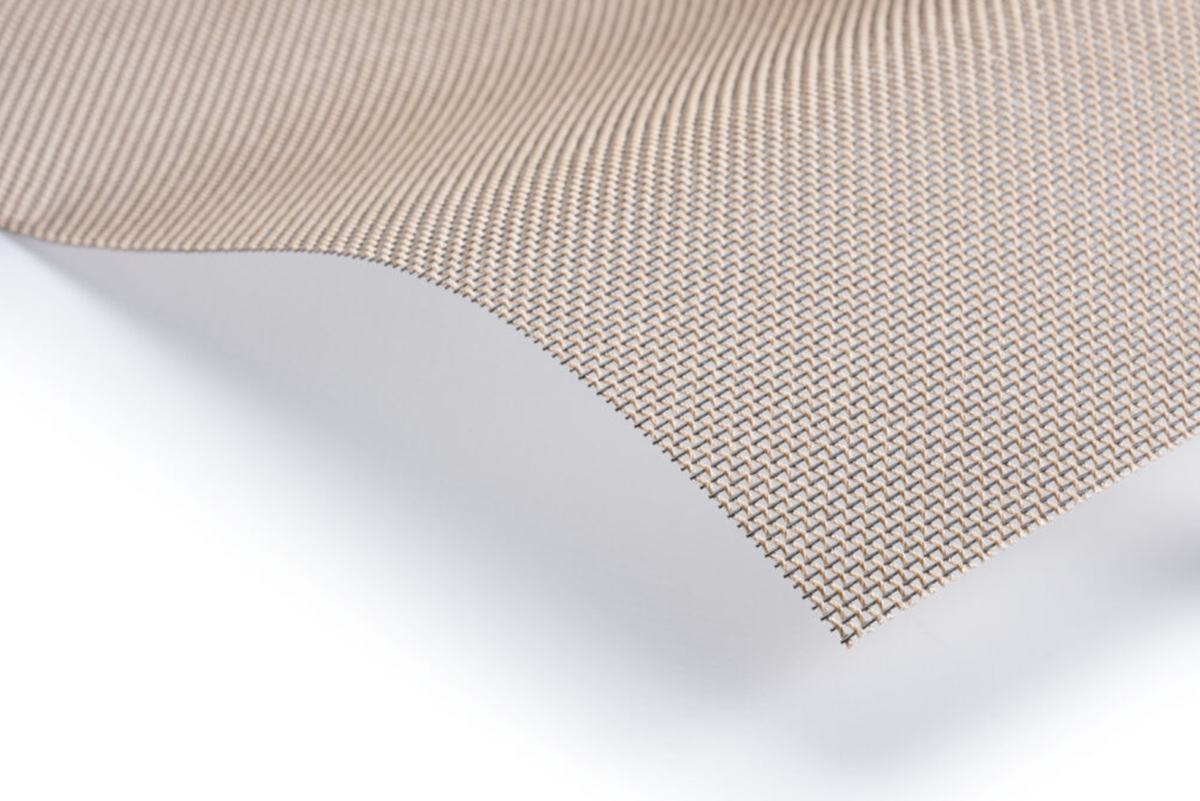

2020 – Conducto® 3322 process belt for corrugated board applications: upper and lower belt for double facers

The innovative new Conducto® 3322 process belt is the all-in-one solution for standard corrugated board systems. It can be used both as the upper belt and lower belt in double facers. The stable and open weave structure and the design of the belt deliver numerous benefits for corrugated board production operations.

The durable belt is produced from polyester mesh with interwoven bronze wires. Its characteristics have been tailored specifically to the requirements of corrugated board production. The Conducto® 3322 therefore facilitates increased production speeds, reduced energy and glue consumption, as well as better steam extraction. Thanks to its special thermosetting, the permanently antistatic, Atex-certified process belt for corrugated board displays exceptional dimensional stability. This also helps reduce additional installation costs. The characteristics of the belt remain constant throughout its entire service life. The Conducto® 3322 also ensures improved flatness and stackability of the corrugated board sheets. As a traction belt/lower belt, the GKD innovation is available either with or without silicone coating. Matching GKD belt feeding tools also make belt changes a breeze.

2019 – Glass hybrid belt 2.0: optimized for use in wide double-belt ovens

With extreme transverse stability and high tensile strength, the enhancement of the GKD glass hybrid belt sets new standards while retaining the same excellent air permeability. Even at large belt widths of more than 5 meters, the conveyor belt reliably displays all of its advantages. Web bonding in wide double-belt ovens is now more efficient. The new glass hybrid belt and its special mesh in detail: The combination of fiberglass and metal unites the advantages of both materials in one belt. Flexible, light fiberglass in the warp direction prevents the mesh from expanding with the heat. The dimensions of the conveyor belt remain stable across the entire temperature range. Metallic weft wires woven in the weft direction ensure the necessary transverse stability in applications with large weaving widths and where strong product shrinking forces are at play. Thanks to the innovative GKD anti-stick coating of the belt, it is also possible to process highly adhesive products – without soiling the belt mesh. The improved glass hybrid belt offers ideal prerequisites for the efficient production of voluminous fiber felts, for which the magnetic double-belt design is suspended magnetically in a double-belt oven. The low weight of the belt per unit area combined with a large magnetic portion is a considerable advantage.

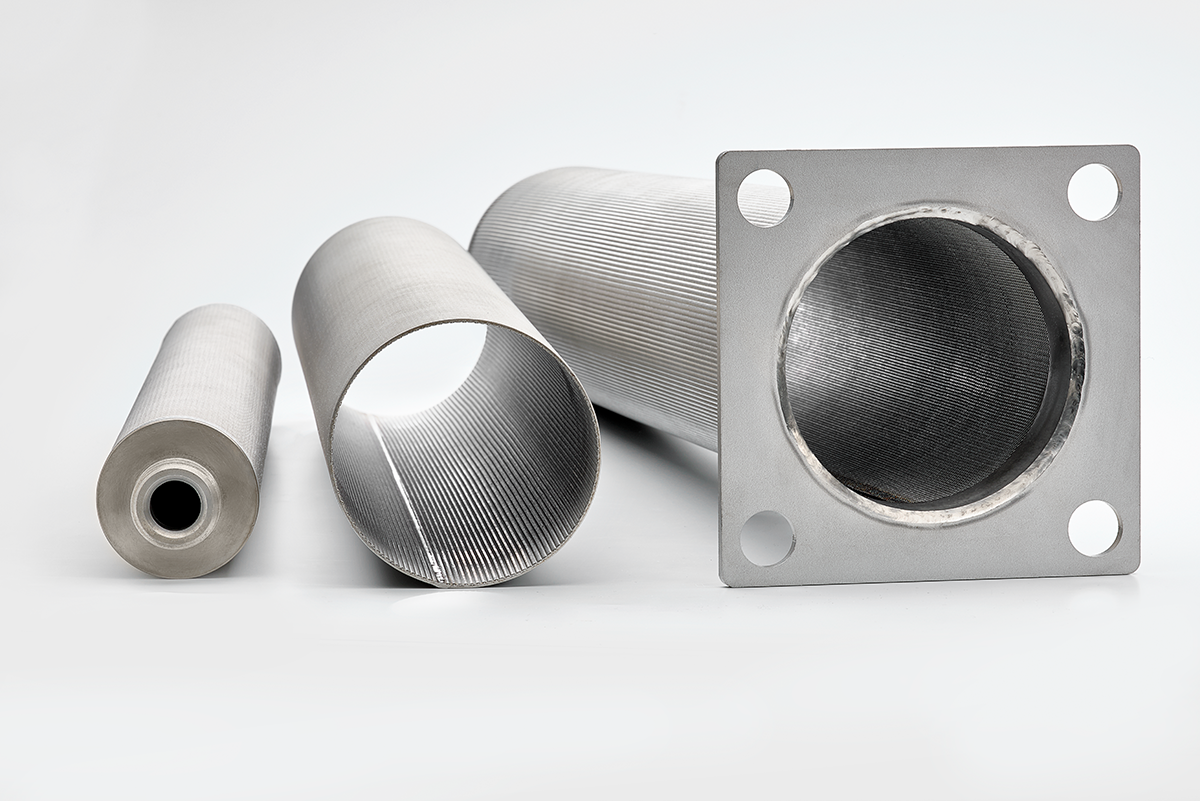

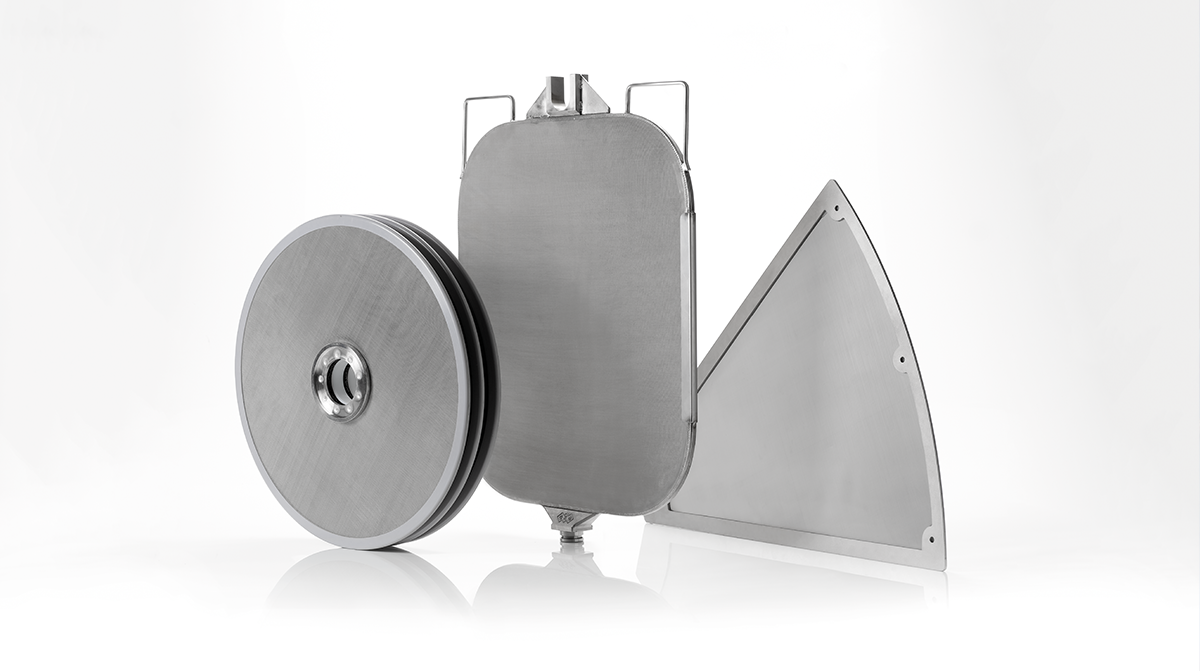

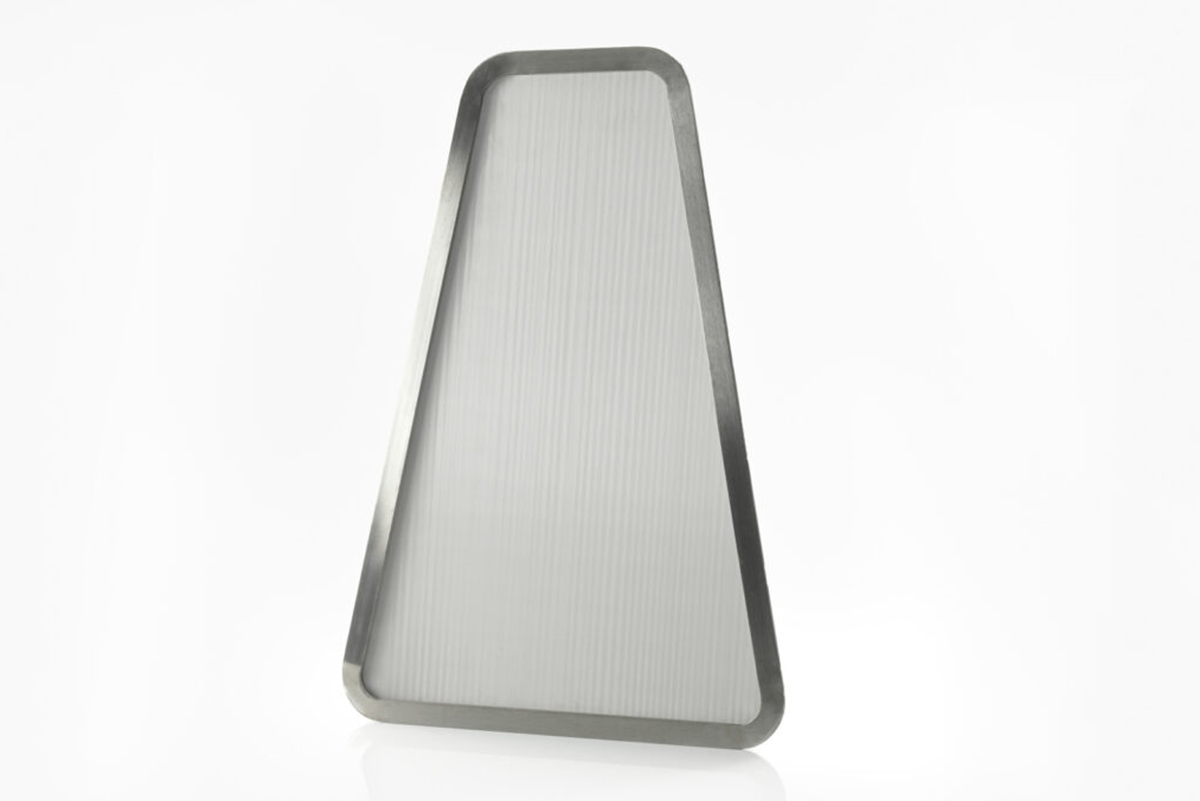

2019 – Trimetric: new filter medium for more efficient hot gas filtration

The high-performance Trimetric filter medium combines everything that highly efficient hot gas filtration requires: great porosity, high retention rates, thermal resistance up to 600 °C, mechanical robustness to vibrations, regenerability during operation, and external cleaning. Trimetric is plastic-free and consists of four-ply metallic, sintered laminate – the first-time combination of optimized dutch weave and stainless steel fibrous fleece. The high efficiency of this combination developed by GKD was first proven in a study by the Institute for Micro Process Engineering (IMVT) and is now available in practice in the form of Trimetric. The inherently stable Trimetric filter elements can be easily employed in all designs of standard dust filters and also in existing cartridge filter systems without alteration. Use in bag filter systems requires only minor modifications to the fastening elements of the respective filter housing. Trimetric filter elements do not require a support basket, and their good weldability ensures secure sealing between the raw gas side and the clean gas side. Cleaning outside the filter housing enables multiple reuse. The length of the cartridges is not limited. Any external diameter from 60 to 600 millimeters is possible. In short: Trimetric filter media make a long-term contribution to increasing the process efficiency and cost-effectiveness of processing systems. The option of dust filtration at high temperatures makes it possible to achieve increases in energy efficiency while also reducing carbon emissions.

2019 – Microfilter crucible for more efficient and precise thermogravimetric analyses

Research into improving microplastics analysis originated from the innovative microfilter crucible for thermogravimetric analysis. The result: For the first time, the sample filter, made of optimized dutch weave, and sample holder are combined. The innovative filter crucible arose from joint research and development work by the German Federal Institute for Materials Research and Testing (BAM), the German Federal Environmental Agency (UBA), and GKD in the research project RUSEKU (Representative investigation strategies for an integrative system understanding of specific release of plastics into the environment). The project examined the advantages of the crucible for ultrafine filtration and analysis of liquids over the course of a year based on microplastics analytics. Increased analytical accuracy and a significant time saving for lab work were confirmed. Thanks to its design and architecture, the TGA crucible can be used directly, sample preparation is simplified, recovery rates are increased, and particle loss and contamination are reduced. The filter crucible can be used for many different applications. It ensures efficient filtration and analysis of liquids with low particulate loads – not only when it comes to microplastics. You can find more information and details here: TGA microfilter crucible.

2017 – Filter for microplastics

Tire abrasion from road traffic is responsible for around one third of total annual microplastic emissions. The RAU project, which is sponsored by Germany’s Federal Ministry of Education and Research (BMBF), measures the levels of emissions that find their way into wastewater as a result of road traffic. The high-tech Porometric mesh from GKD removes microplastics down to a size of just 20 micrometers from wastewater. Thanks to its outstanding properties, the GKD mesh received the AFS Award in 2017, one of the most prestigious innovation awards for filter media.

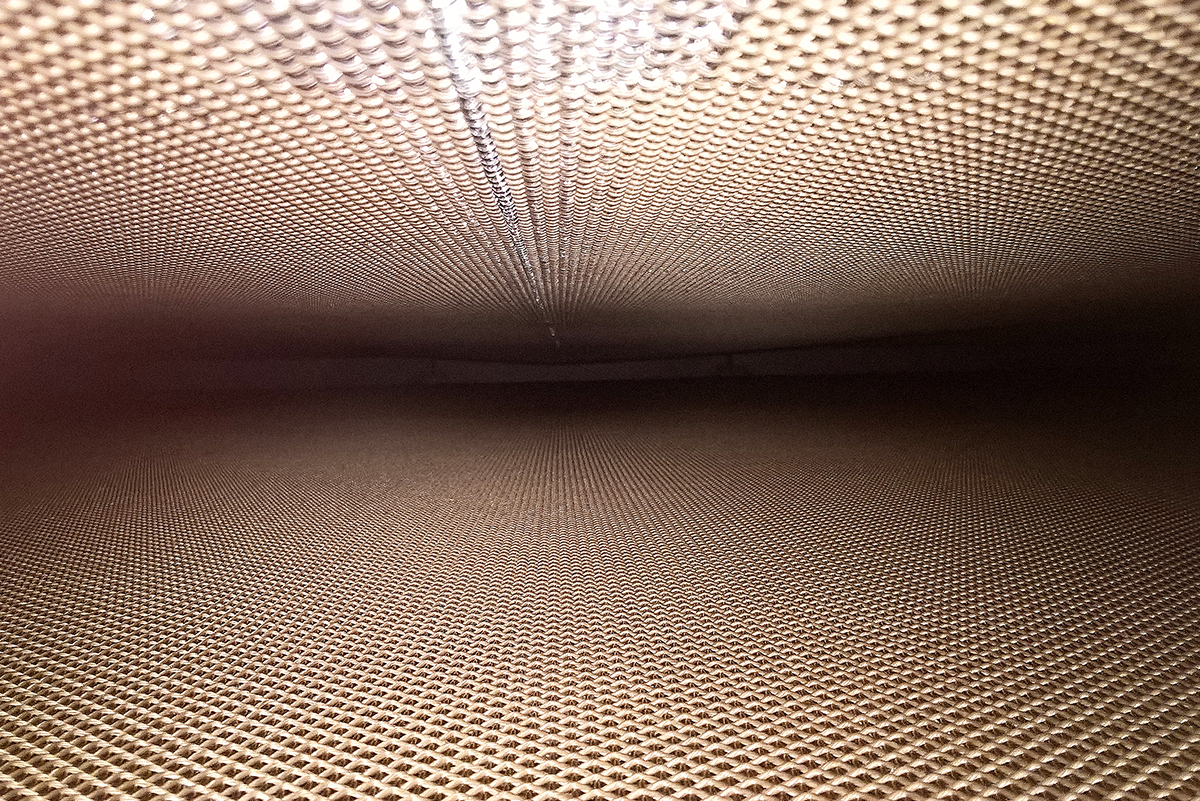

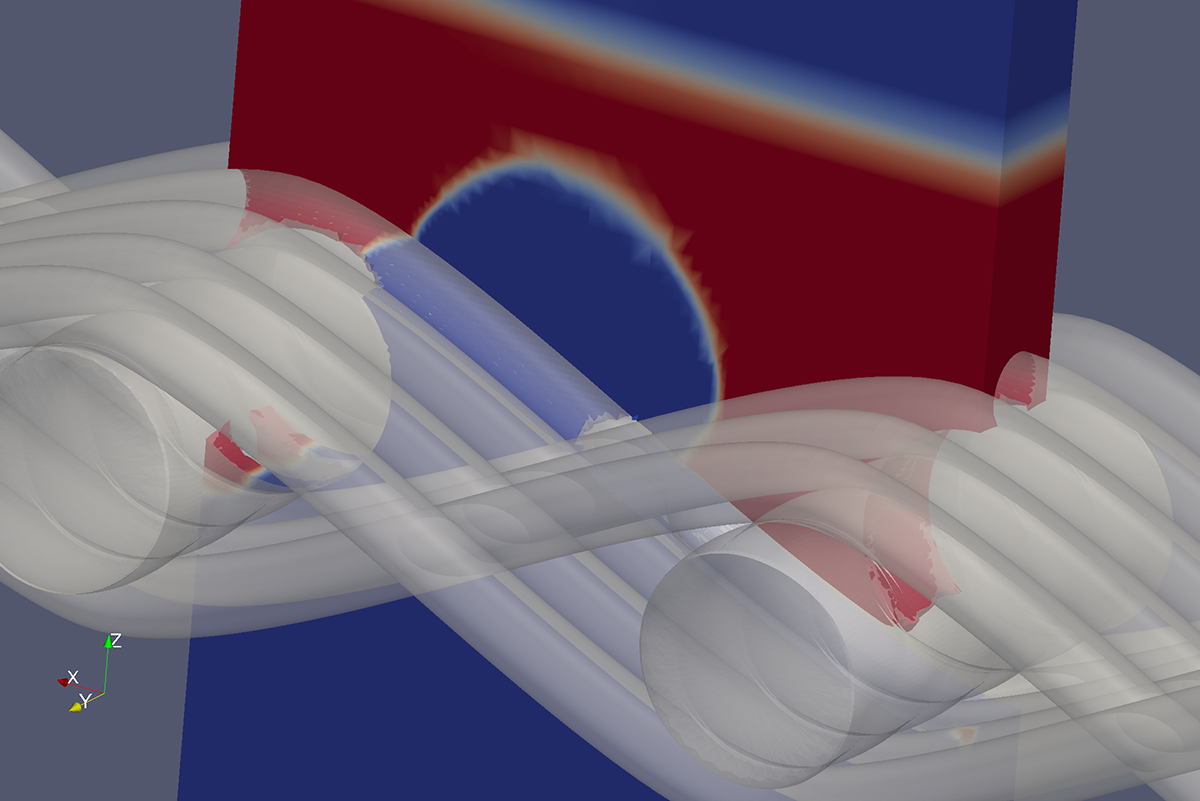

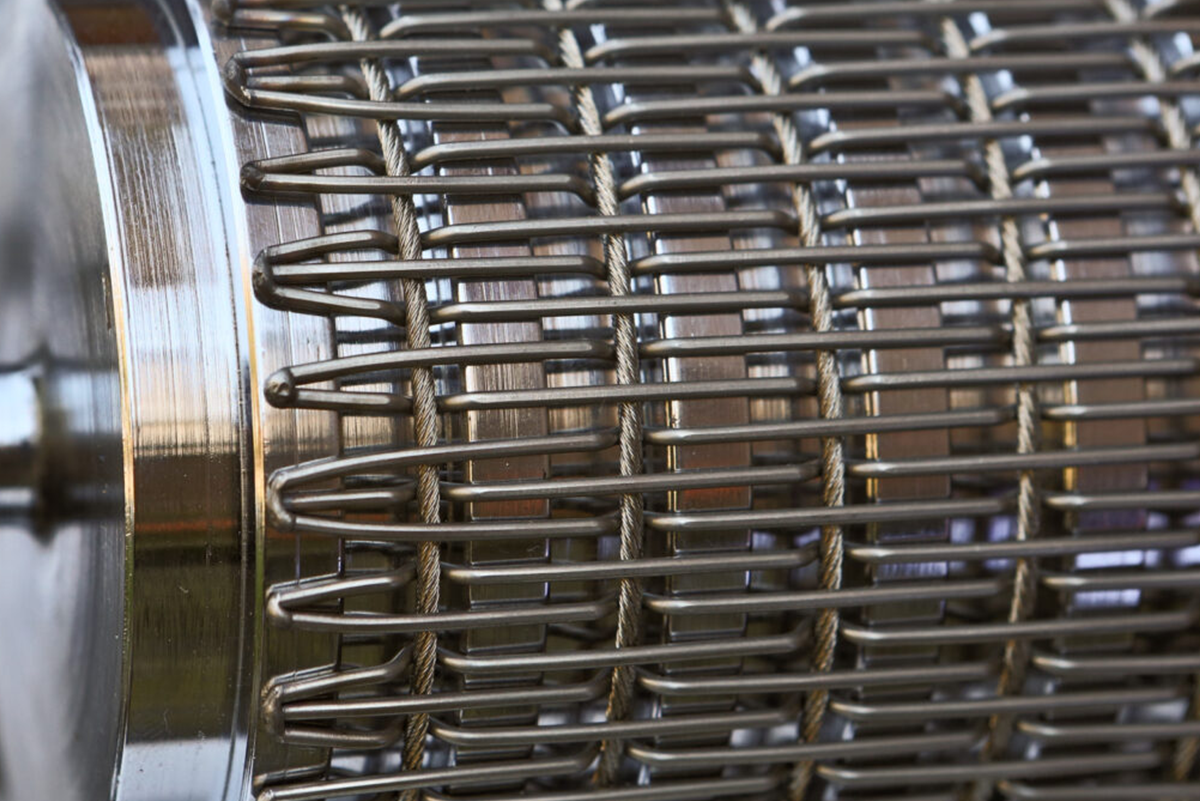

2017 – New filtration mesh for a higher flow rate at low pore velocities

The new high-tech Porometric filtration mesh for highly efficient filtration of water, oil, gas, and polymers has been the recipient of the AFS Award, one of the most highly regarded innovation awards for filter media. The inspiration for the design of the novel filtration mesh came from a comprehensive experimental study on the erosion behavior of filter media in pipelines, to which GKD contributed its CFD simulations. This made clear the relationship between inflow velocity and pore velocity distribution. Armed with the knowledge that the local velocity in the pores can be reduced through higher volume porosity of the filtration mesh, GKD began development on Porometric. The high-tech filtration mesh in detail: very open, three-dimensional weave; high permeability; reduction of the local pore velocity by up to 40 % with constant volumetric flow, simultaneous increase of the flow rate; very good backwashability and low energy consumption/lower pump power required. The Porometric filtration mesh possesses the highest permeability in the world in combination with a high dirt-holding capacity. Its properties offer decisive advantages in transporting oil and gas as well as in water processing – whether in municipal and industrial water treatment plants for filtering out microorganisms, preparing service and process water, and producing fresh water, in shipping for ballast water filtration, or in plastic-free water filtration, for example.

2017 – Glass hybrid belt: combines the advantages of fiberglass and metal in one mesh

GKD is treading completely new paths with the glass hybrid belt. By combining fiberglass with metal, the advantages of both materials are combined in a single product. Because the flexible, lightweight glass fibers in the warp direction do not expand when heated, the dimensions of the mesh remain stable across the entire temperature spectrum. The metallic weft wires woven in the transverse direction lend the mesh the level of lateral stability required in applications with large working widths in which the product exerts strong shrinkage forces. This innovation is rounded off with non-stick coating, which enables even highly adhesive products to be processed on this belt without the belt becoming soiled. The main area of application will be the manufacturing of voluminous nonwovens, in which the belt is magnetically lifted in a double-belt dryer. The low weight per unit area with a simultaneously high magnetic share is a great advantage here.

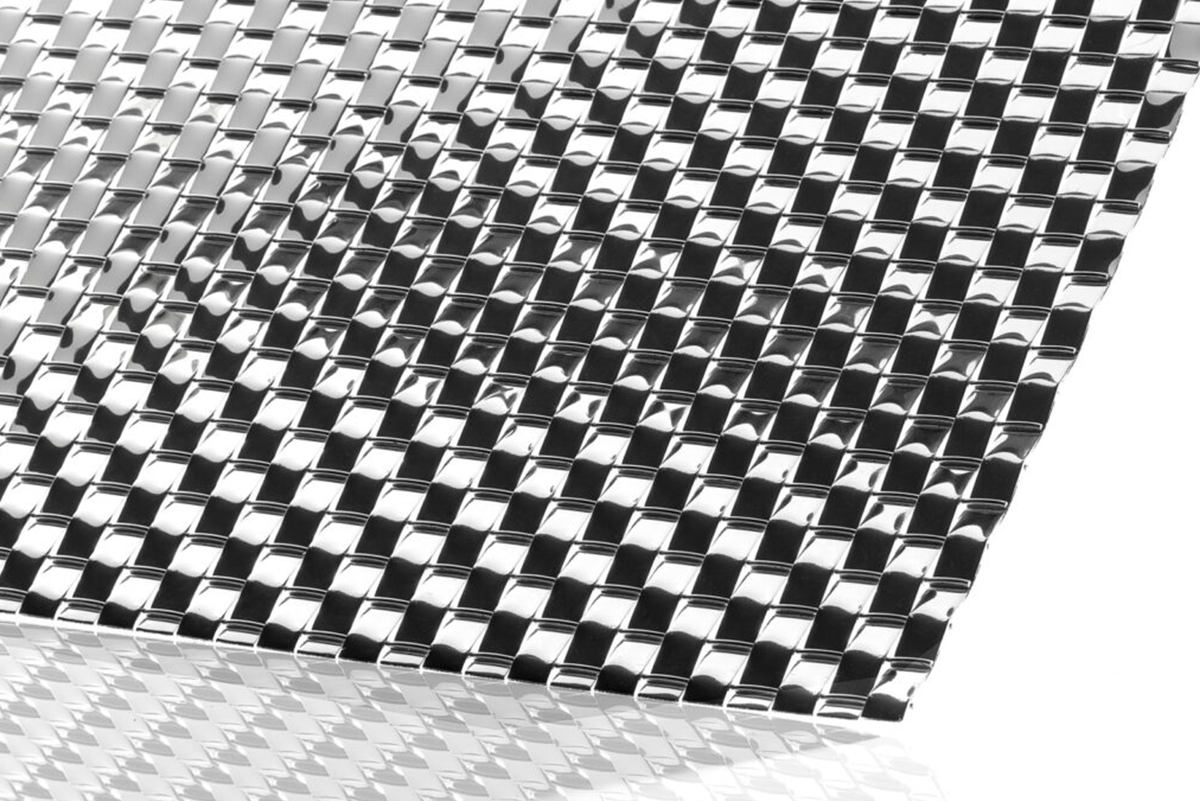

2016 – New filtration mesh design for high throughput and optimum backwashability

Leading manufacturers of filter equipment were looking for a filter medium that represents a genuine alternative to existing sand filter systems for mechanical preparation of surface water, wastewater, and sea water. GKD therefore faced a tough challenge: to develop a fine filter medium for hydrostatic filtration that reliably separates 99 percent of all particles > 6 µm and also offers a high throughput. As a proven supplier that had been delivering sophisticated filter media for many years, GKD then presented the flow-optimized 6 µm ODW 6 dutch weave solution. This increases the flow rate by up to 25 percent, while maintaining the same overall aperture. The innovative filtration mesh design, produced from stainless steel, combines consistently precise selectivity in the micro-filtration range with high permeability, stability, and backwashability.

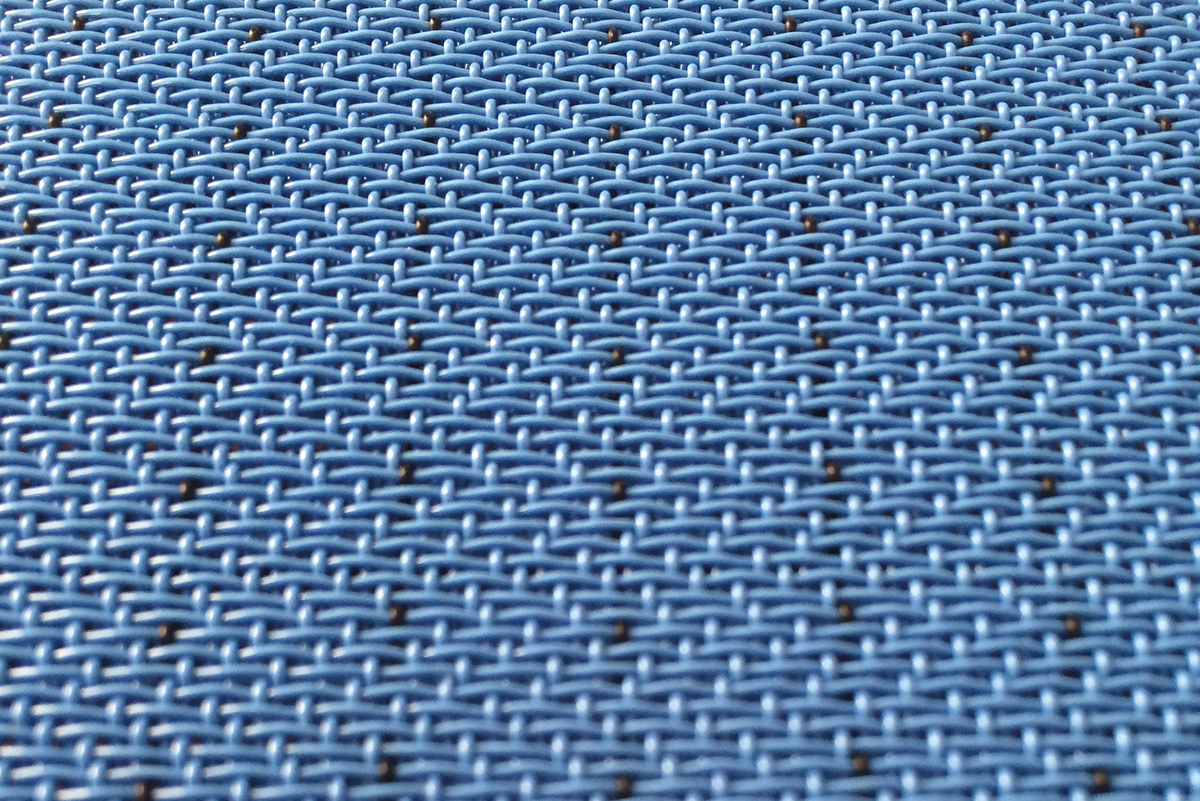

2016 – New Conductive 7690 forming belt for spunbond applications

The great art in forming spunbond lies in achieving good grip of the filaments when they are placed onto the forming belt, while at the same time ensuring good release properties of the spunbond at the end of the belt. In addition to this, it must be possible to clean forming belts easily from any process-based soiling caused by polymer drops, which in the end is crucial for a longer service life. The innovative web structure of the CONDUCTIVE 7690 combines all of these attributes. Unlike other process belts, the grippy surface does not need to be roughened up in a costly mechanical process before use. This reduces machine downtimes. With the non-marking pin seam and interwoven, carbon-coated filaments for electrostatic discharge, critical materials can be produced for high-quality products using high speed systems.

2016 – Breakthrough in filter mesh development

With regard to filter meshes, the bubble point test has been the standard for many years for quality control and quality assurance. It is used to determine the diameter of the largest pore in a filter medium. This is done by translating the pressure value measured in a laboratory test into a pore diameter value using a predefined capillary pressure constant. To get an absolute value for the diameter of the largest pore, time-consuming screenings were always necessary. Now, through the simulation of the bubble point test and the application of capillary pressure constants determined from the simulation, GKD has found a method with which the maximum pore size for all standard woven filter meshes can be precisely established in no time at all. As international technology leader for woven filter media we use these “Computational Fluid Dynamics” (CFD) tools for more than just quality control. The method is also uniquely suitable for purposeful development of new precision filter meshes or for application-specific adjustment of existing woven filter mesh types to meet customer-specified bubble point values.

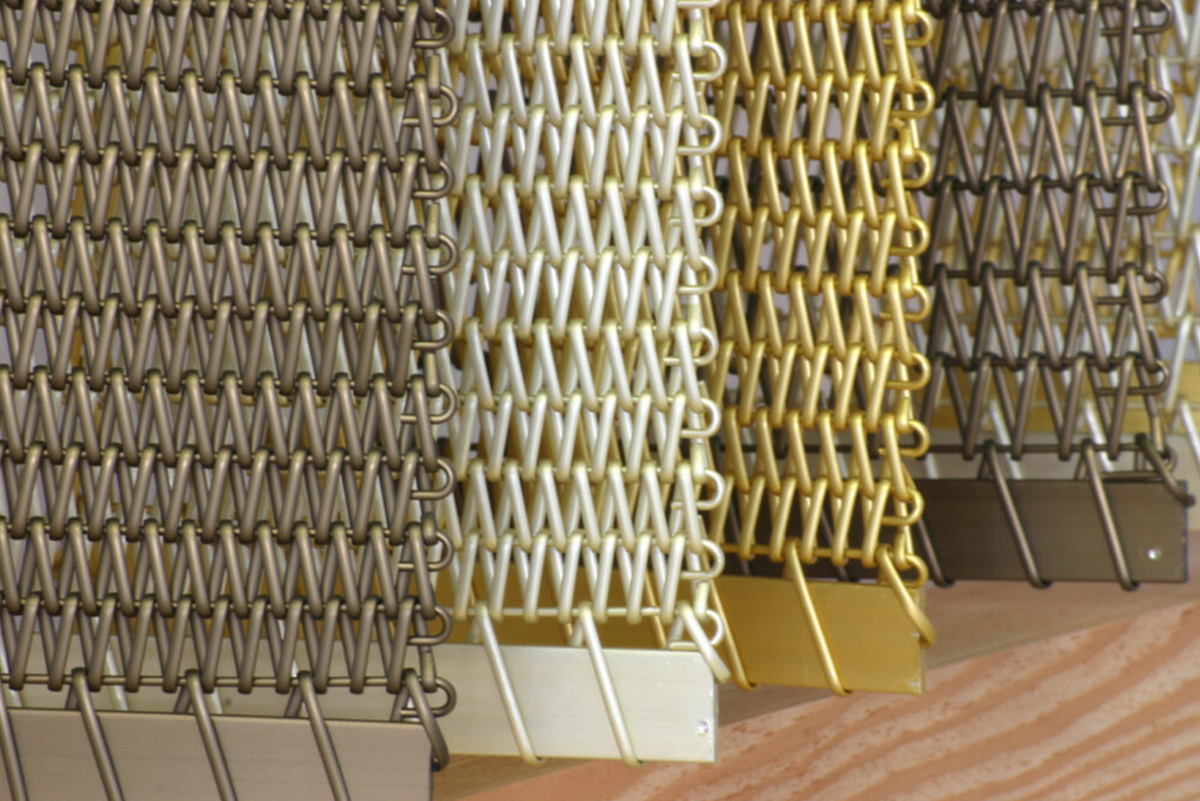

2014 – Architectural mesh for better lighting at the workplace

The combination of good sound-absorbing properties and good interior lighting using system ceilings is difficult to achieve with conventional drywall construction systems. Together with Bartenbach, one of the world’s leading lighting designers, GKD designed a system that optimally achieves this objective: Atlantic Glow. This highly reflective ceiling not only looks elegant, it also combines good sound-absorbing properties with a significant improvement in interior lighting. Atlantic Glow is also available in various colors.

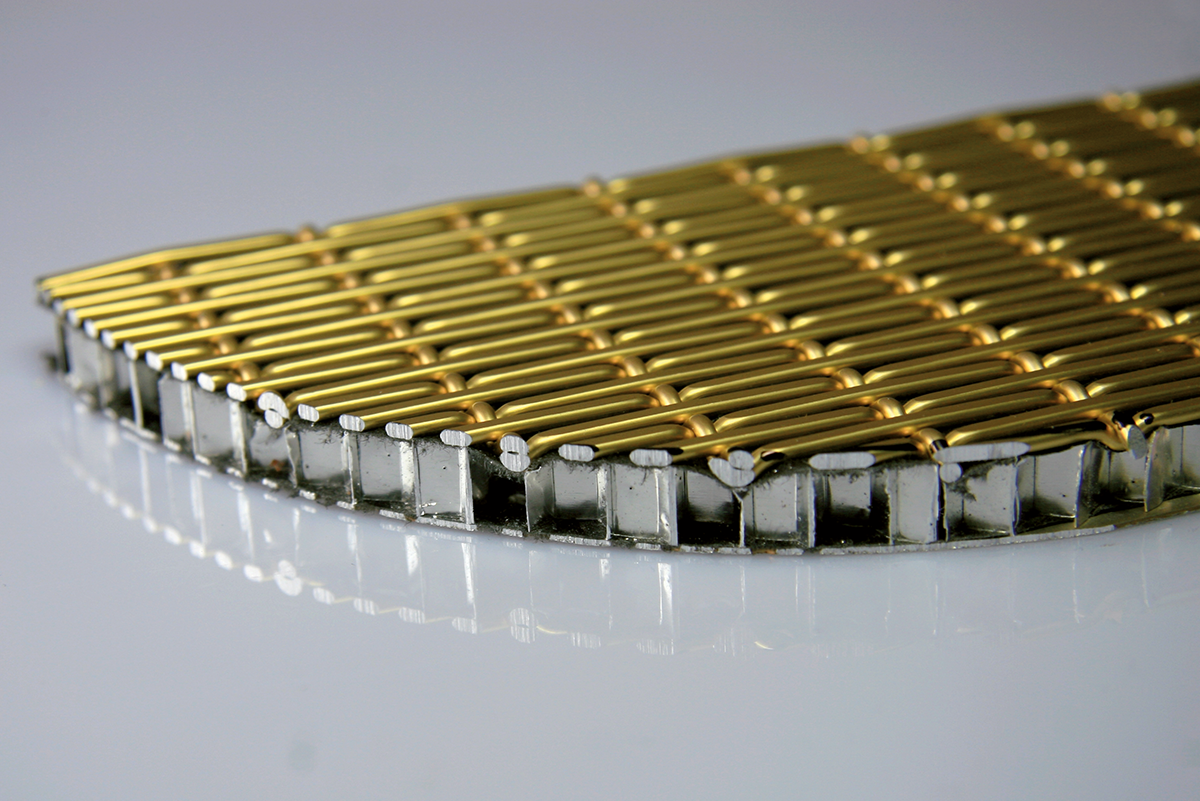

2013 – Silentmesh CMP fabric: adopted from nature

Silentmesh CMP fabrics are made of flexible metal mesh fabric, which is mounted to aluminum honeycombs.

This composite material (CMP) can be used to produce extremely stable yet also very lightweight mesh panels. The Silentmesh version of these panels ensures a high degree of room-based acoustic comfort.

SILENTMESH CMP BENEFITS:

- CMP mesh panels from the Silentmesh range are ideally suited to large-area wall cladding and suspended ceiling applications.

- The composite mesh is predestined for grid-free and sag-free solutions.

- The mesh panels can be cut into virtually any shape.

- Silentmesh CMP meshes boast outstanding sound-absorbing properties.

- Sound absorption values between 0.85 and 1.00 αw.

2012 – Architectural mesh as an acoustic element

GKD meshes made of stainless steel or aluminum are also an architectural highlight inside buildings. When used in suspended ceilings, special emphasis is placed on the acoustic properties of the components used. Since 2012, GKD’s system solution has been called Silentmesh: Here, we combine our metal mesh with acoustic fleece or other sound-absorbing materials to produce a system with a sound absorption coefficient proven in tests. The result is a range of innovative complete solutions for a high level of room-based acoustic comfort that also impress in architectural terms.

2011 – Filtering particles of various sizes with volumetric mesh

In the field of exhaust gas filtration there has long been a requirement for meshes that filter particles of different sizes while at the same time minimizing pressure loss. The volumetric mesh is the answer to this challenge. This is a further development of the TELA® mesh or 5-heddle weave developed by GKD back in the 1930s. The special weave of the volumetric mesh enables three-dimensional structures that perform this task. Moreover, the efficiency of the volumetric mesh is further enhanced by modern material combinations.

2009 – Doublebacker belts in corrugated board production

In the double facer in corrugated board production, the moistness of the glue has to be removed from corrugated board quickly and in an energy-efficient way. For this purpose, the product is pressed by belts against a heated surface. In 2009 GKD developed special process belts which represented a far more reliable alternative to the felt belts used up to then; the open mesh structure of the GKD belts has guaranteed even evaporation of steam at considerably higher production speeds ever since. The even layer of residual moisture ensures that the sheets remain flat. Furthermore, bronze wires have been woven into the polyester mesh, which dissipate electrostatic charges from the conveyed material safely and reliably.

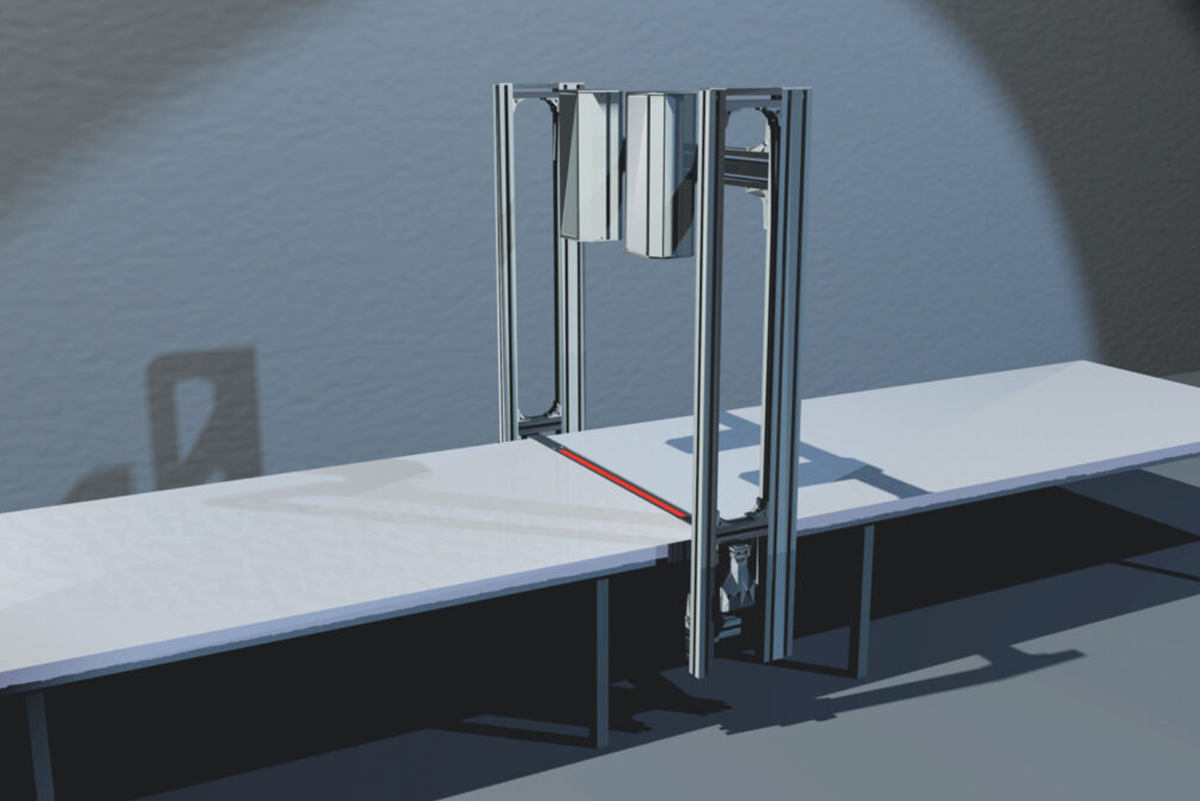

2008 – Camera inspection of products

Filters without fault tolerances are required for many demanding applications. Thanks to our automated camera inspection system, which is integrated inline in various positions throughout the manufacturing process, we have been able to measure 100% of apertures of a filtration mesh for a number of years. This checks and documents every single aperture in the mesh. As such, we offer our customers far more than just a filtration product – we deliver a solution they can totally rely on.

2006 – Architectural mesh meets billboard: MEDIAMESH®

MEDIAMESH® is a particularly impressive example of the GKD engineers’ ability to “think outside the box” and devise completely new solutions. MEDIAMESH® is the idea of a transparent media façade based on modern LED technology: Fine, weather-proof tubes fitted with LEDs are woven into the GKD stainless steel mesh. The result is a high-resolution façade in accordance with customer specifications that can display all kinds of media content and which, in contrast to a traditional billboard, can be mounted in front of a glass façade. This grants the residents or employees inside the building an unhindered view of the outside surroundings, while offering viewers outside a truly cinematic experience whether during the day or in the night. GKD sees a trend here extending far beyond the aims of advertisers. MEDIAMESH® unleashes a whole range of new opportunities for buildings, companies or cities to communicate with their environment and visitors in public spaces.

2005 – Architectural mesh for energy optimization

For years, GKD has also been working highly successfully on optimizing architectural mesh as a solution for effective solar protection. As a result, our meshes remain transparent when looking from the inside to the outside. When the sun is high in the sky during summer, however, the mesh reflects the sunlight, thus reducing solar input and thereby also the need for air conditioning. In practical tests, this solution enables wall temperatures to be reduced by up to 19%. When the sun is low in winter, the transparency of the mesh permits solar irradiation, thus reducing heating costs.

2005 – CONDUCTO®: process belts with ATEX certification

GKD was the first supplier to offer ATEX-certified process belts in the form of the CONDUCTO® process belt. This innovation was possible because the weavers at GKD succeeded in combining plastic and metal, despite the different properties of the materials, to form a homogeneous and stable fabric. Since then, bronze wires within a polyester fabric have been discharging any electrostatic charges away from the transported materials in a safe and reliable way. Today, CONDUCTO® is used in wood processing, nonwovens production and in other industries.

2000 – Colors make all the difference

TAfter virtually all GKD architectural meshes were made from stainless steel for many years, architects increasingly began to look for colored solutions for façade mesh, ceiling suspensions or wall cladding. Aluminum seemed the ideal solution. However, the challenge here was that the existing dip tanks for batch anodization used in industry were too small for the mesh panels from GKD. Together with an industry partner, GKD developed a new continuous anodization process in which the aluminum wire is anodized before weaving and not, as was previously the case, the finished product. Thanks to this continuous process, large volumes of wire are available at a constantly high quality.

1992 – Conveyor belts under the magnifying glass

The term “architectural mesh” did not yet exist in 1992, when architect Dominique Perrault was searching for a textile yet non-flammable material for his project at the National Library of France in Paris. He knew, however, that it was to be a metal mesh, and he discovered that GKD manufactured metal mesh for industry with a variety of qualities. Together with Perrault, GKD developed twelve different stainless steel meshes for various applications at the National Library. Internally, the mesh was often referred to as “conveyor belts under the magnifying glass”. A new business unit for GKD and a whole new architectural category had come into being: Architectural mesh. Many international architects took this idea and interpreted it in new ways. Architects have always enjoyed bringing materials used in industry into the world of architecture, and metal mesh made the transition a in particularly convincing fashion. After all, not only the visual effect is the primary concern, but also the textile character combined with tensibility and the ability to use the material across large surfaces. GKD’s ability to weave metal mesh with widths of up to eight meters and up to 100 meters long unleashed entirely new possibilities for architects in terms of scale in or on the building.

1990 – The invention of metal architectural fabric

At the start of the 1990s, French architect Dominique Perrault harnessed the architectural design potential offered by metal fabrics during construction of the new National Library of France (BNF) in Paris. In collaboration with the GKD Group, he created twelve different exterior and interior applications for the same number of metal fabrics. Metal fabric is today globally established in high-end construction projects.

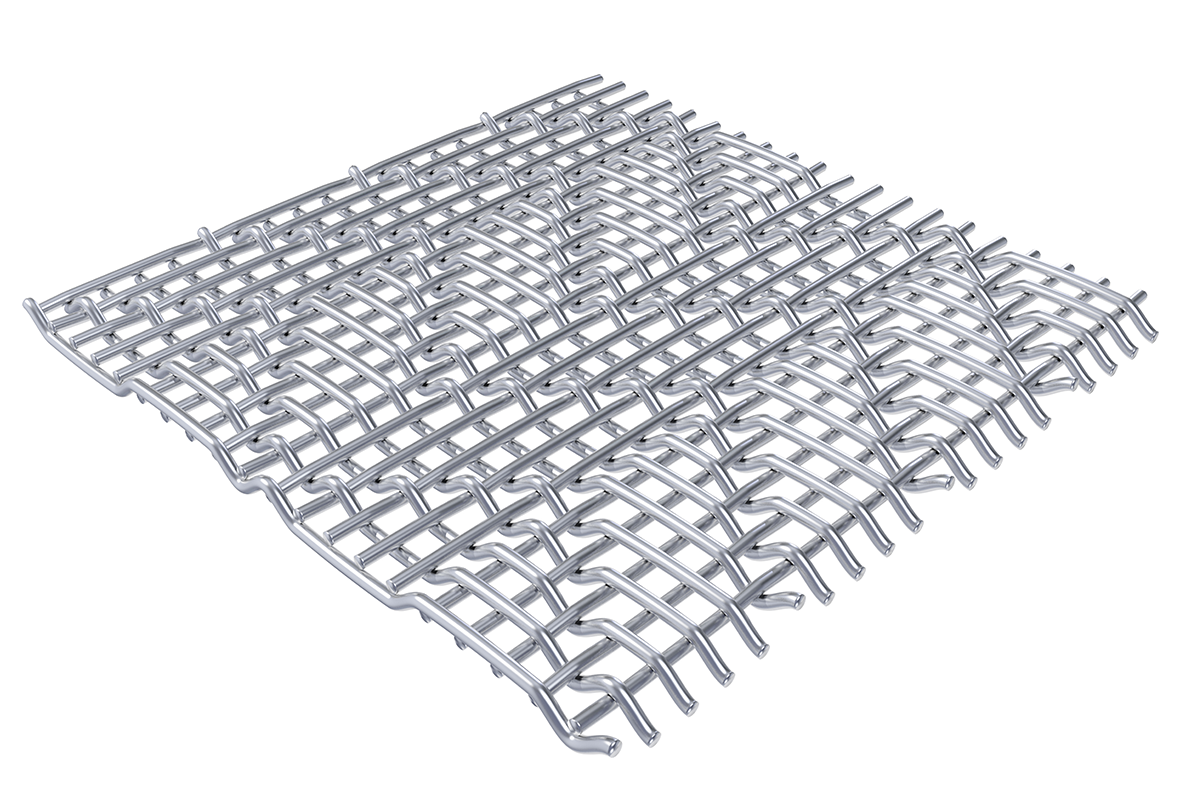

1970 – Self-regulating process belts

In the 1960s, self-regulating process belts, TRACKMATIC™ belts from GKD, were far more than just an innovation: External control units were made redundant, machines became more compact and service lives were raised considerably. This was all made possible by a new weave type that for the first time enabled rows of V-crimps on the underside of a process belt, while the top of the belt was still smooth. These V-crimps are guided in grooved rolls, which effectively prevents the process belts from running out of alignment. Since the market launch, we have in particular concentrated on enhancing the materials employed. For example, Teflon-coated wires are used as warp wires in the food production industry. For hygiene products we manufacture process belts with Kevlar warp wires which also allow high-speed production lines to be equipped with optimal reliability.

1960 – Polyester filter belts

At the beginning of the 1960s, GKD combined two industrial innovations in a single new product: GKD wove the “Type 1003” filter belt from a monofilament polyester wire for the newly developed belt press. As neither looms nor weave patterns existed for the new material, GKD built the machine itself. And so TELA® mesh made of monofilament polyester was specially developed for use with belt presses. Its smooth upper surface ensures reliable cake discharge even today, while the coarse underside offers good belt-cleaning properties. Our filter belt 1003 remains a highly successful solution to this day.

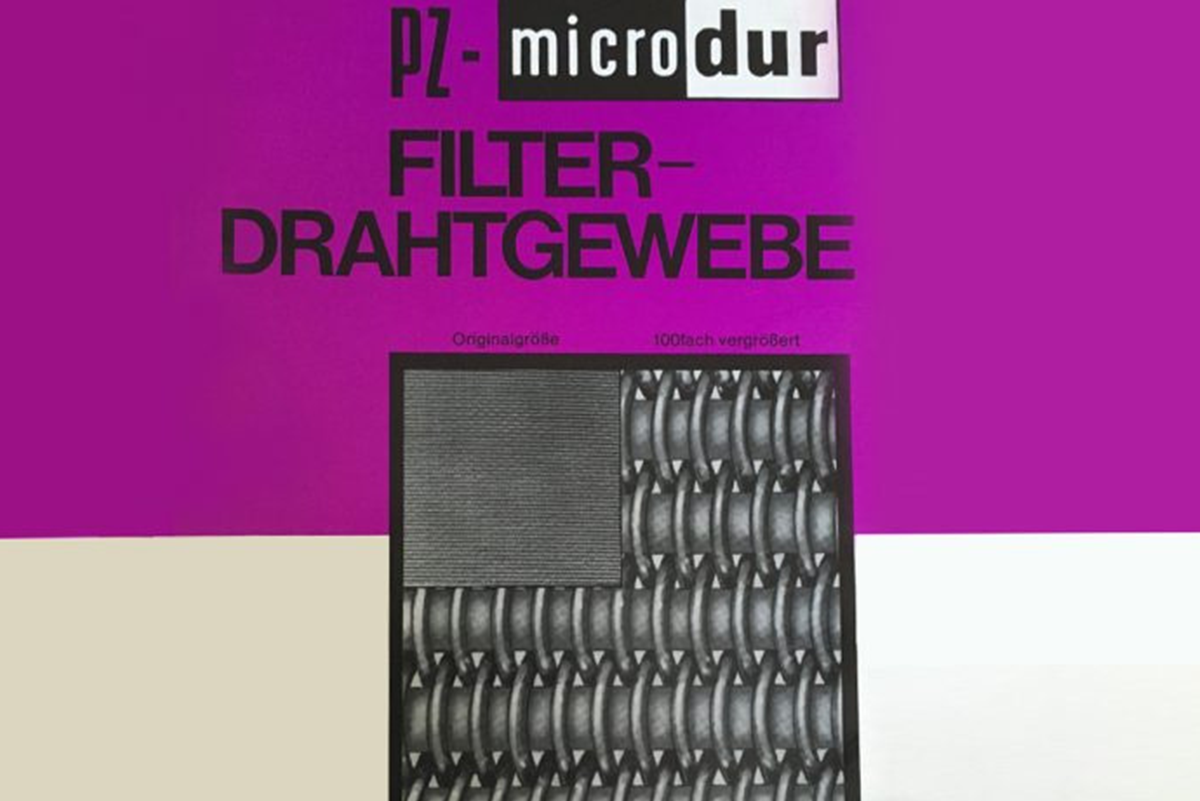

1950 – Microdur weave for heavy-duty applications

Industrial plants became ever larger in the 1950s. This led to the demand for more efficient filtration meshes. However, plain dutch weave mesh, which until that time was a proven solution, had reached its technological limits. A new generation of meshes was therefore needed, meshes that could guarantee a high and durable level of pore stability even across large filter areas. The GKD engineers found the solution in reversed dutch weave, a mesh structure combining a high number of thin warp wires and a small number of thick weft wires. This mesh, dubbed “Microdur“, offered the desired properties. This fine (“Micro”) and stable (“dur”) mesh still offers a long service life and durably safe and reliable filtration of both gases and liquids to this day.

1930 – TELA® weave combating blocked pores

Until the 1930s, metal meshes were mainly woven with square weaves. The problem, however, was that especially in coal slurry dewatering applications in the mining industry, these quickly became blocked and were difficult to clean. Josef Kufferath, the grandfather of today’s owners, developed a mesh with oblong weave and a smooth top surface: the TELA® or 5-heddle atlas weave, which was later patented, was born. Even today, the smooth upper surface enables more reliable filter cake discharge than other weave types. The oblong mesh ensures good filter cake dewatering, while the underside prevents the pores from becoming blocked. The original idea for the TELA® weave, however, came from elsewhere. Together with a friend of his, a dentist, Josef Kufferath was trying to create a mesh that was friendly to the palate and at the same time smooth to the tongue to be used as a stabilizing material for dentures. Its use in filtration applications, however, proved to be considerably more sustainable …